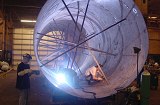

Schebler Specialty Fab provides custom tanks built for specific applications.

That’s what we do - we provide individualized solutions. At Schebler Specialty Fab, we are experts at designing and producing stainless steel tanks that will stand up to corrosive materials. Each tank is built-to-order for a specific customer and a specific purpose.

Many tanks we fabricate are used for acids, alcohol, bio-diesel, chemicals, cryogens, de-aeration, fermentation, fertilizer, fuel and grain. Typically, tanks range from 6 inches to 16 feet in diameter and up to 50 feet in length. While our projects usually involve completing one or two tanks, we support low volume production tanks as well.

The custom tanks we produce are largely constructed of Stainless Steel, Steel Sheet Metal, Heavy Steel Plate and Galvanized/coated metal.

Aluminum with processes such as TIG Welding, MIG Welding, Rolling, Laser cutting, Painting & Coating, Forming and Tube bending.

_730_420_87auto_s_c1.jpg)

_730_420_87auto_s_c1.jpg)

_730_420_87auto_s_c1.jpg)

_730_420_87auto_s_c1.jpg)

_730_420_87auto_s_c1.jpg)

_730_420_87auto_s_c1.jpg)

_160_105_87auto_s_c1.jpg)

_160_105_87auto_s_c1.jpg)

_160_105_87auto_s_c1.jpg)

_160_105_87auto_s_c1.jpg)

_160_105_87auto_s_c1.jpg)

_160_105_87auto_s_c1.jpg)